Using PGRs to Manage Apple Preharvest Drop, Fruit Maturity, and Harvest Timing

go.ncsu.edu/readext?873797

en Español / em Português

El inglés es el idioma de control de esta página. En la medida en que haya algún conflicto entre la traducción al inglés y la traducción, el inglés prevalece.

Al hacer clic en el enlace de traducción se activa un servicio de traducción gratuito para convertir la página al español. Al igual que con cualquier traducción por Internet, la conversión no es sensible al contexto y puede que no traduzca el texto en su significado original. NC State Extension no garantiza la exactitud del texto traducido. Por favor, tenga en cuenta que algunas aplicaciones y/o servicios pueden no funcionar como se espera cuando se traducen.

Português

Inglês é o idioma de controle desta página. Na medida que haja algum conflito entre o texto original em Inglês e a tradução, o Inglês prevalece.

Ao clicar no link de tradução, um serviço gratuito de tradução será ativado para converter a página para o Português. Como em qualquer tradução pela internet, a conversão não é sensivel ao contexto e pode não ocorrer a tradução para o significado orginal. O serviço de Extensão da Carolina do Norte (NC State Extension) não garante a exatidão do texto traduzido. Por favor, observe que algumas funções ou serviços podem não funcionar como esperado após a tradução.

English

English is the controlling language of this page. To the extent there is any conflict between the English text and the translation, English controls.

Clicking on the translation link activates a free translation service to convert the page to Spanish. As with any Internet translation, the conversion is not context-sensitive and may not translate the text to its original meaning. NC State Extension does not guarantee the accuracy of the translated text. Please note that some applications and/or services may not function as expected when translated.

Collapse ▲Why is this important?

On susceptible varieties, preharvest fruit drop can lead to >30% crop loss in some years. PFD is due to a breakdown of a layer of cells on either side of the abscission zone – where the stem meets the spur – prior to fruit reaching horticultural maturity. Given concerns related to sufficient labor for harvest (especially this year), these harvest management aids can also help stagger harvest timing. Fortunately, multiple plant growth regulators are commercially available to reduce preharvest drop and manage harvest timing.

Preharvest fruit drop of ‘Red Delicious’ apples. NAA and AVG are PGRs that can effectively control PFD with AVG having the added benefit of delaying maturity.

Varieties

Apple varieties differ in their susceptibility to PFD. ‘Honeycrisp’, ‘Red Delicious’, ‘Golden Delicious’, ‘Rome Beauty’, etc. are prone to PFD. Other cultivars, such as ‘Gala’ and ‘Fuji’ do not exhibit PFD. Varieties also differ in the production of ethylene, with ‘Gala’ being a low ethylene producer and ‘Red Delicious’ being a high ethylene variety. Low ethylene varieties are sensitive to AVG and high ethylene are less responsive to AVG.

What should I use?

There are three commercially available products to consider. Use of these specific products will be dictated by several factors, such as: labor availability, marketing (direct vs. wholesale), buyer preference/requirements, etc.

ReTain

ReTain® (AVG; Valent Biosciences) suppresses the production of ethylene in the fruit, which delays maturation of the fruit and breakdown of the abscission zone. AVG is a dose dependent chemistry, is effective in reducing preharvest drop, and has a range of use patterns to achieve specific management goals. Maintaining fruit firmness and prolonging starch conversion to sugar are the main maturity delaying benefits of AVG. There is some evidence that AVG can increase fruit size because the persisting fruit continue to grow (generally at a rate between 0.6 and 1 mm per day). Water core, stem end cracking, and flesh bleeding can be reduced with AVG. Typically; a delay in ripening will result in delayed development of red fruit color. However, if the delayed harvest time means that fruit ripen under conditions that promote red fruit development (sunny days and cool nights) then red fruit color can be increased with AVG.

Timing is critical. For high ethylene producing cultivars, ReTain® must be applied before the climacteric rise in ethylene of the fruit, typically 3-4 weeks before anticipated harvest (WBH). Early season apple varieties are more prone to changes in harvest date due to environmental conditions than later ripening varieties. Therefore, to apply ReTain® at an effective timing for early season varieties, it is important to gauge anticipated harvest dates for early season varieties from bloom date and harvest dates of earlier ripening species, such as peaches.

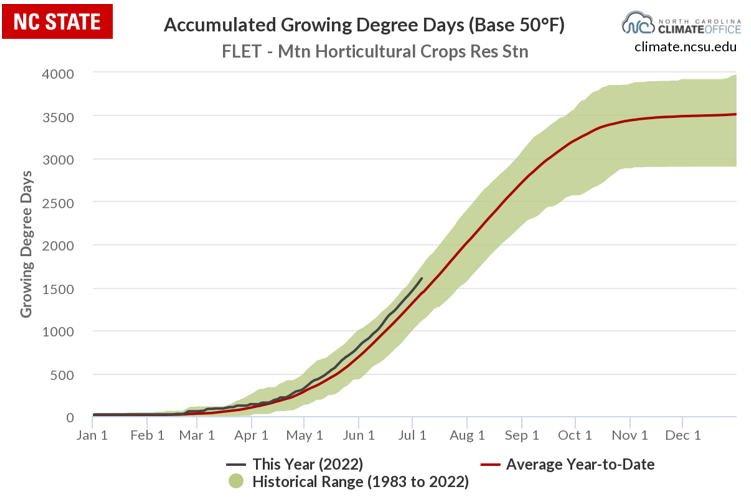

This year (2022), growing degree-day accumulation in Mills River, NC is 171 hours greater than the 39-year average. This suggests that early season cultivars will have advanced maturity relative to a “normal” year. This will need to be taken into consideration with the timing of ReTain® applications, preparation for harvest, and labor availability.

Mountain Horticultural Crops Research Station has accumulated 171 more GDD than the 39 year average to this point in the year.

ReTain® is sold in water soluble pouches and rate recommendations are made off number of pouches per 100 gallons of water. For optimal results, a 100% organosilicone surfactant at 0.05% – 0.1% (6 to 12 fl. oz. per 100 gallons) should be tank mixed with ReTain®. In most cases, the 12 fl. oz rate is recommended. However, the 6 fl. oz. rate should be considered on early maturing cultivars (Gala or earlier) which often mature during prolonged periods of hot weather. Application of ReTain® during slow drying conditions and when there is at least 6 hours of drying time. The PHI for ReTain® is 7 days.

Pending upon the goal of the application and the variety of interest, there is a relatively wide range of application strategies:

- The standard rate of ReTain® is 1 pouch (333 grams) at 3-4 WBH for high ethylene producing varieties. In most years and varieties, this will provide 7-10 days of drop control. For varieties that are sensitive to ReTain® (Gala and Honeycrisp), a ½ pouch per 100 will achieve a similar response.

- To further delay maturity (to obtain benefits of increased fruit size and/or staggering harvest date) a double rate can be applied 3-4 WBH or as a split application of a second pouch.

- For apples that do not ripen uniformly and require multiple harvests (Gala, Honeycrisp, early strains of Fuji, etc.), there is an alternate application strategy. Applying a single pouch of ReTain® at 1 WBH can be used to minimize negative impacts on red fruit color development. This application will not influence the timing of the 1st harvest but will influence fruit maturity of fruit that are destined for later harvests. Even with this application being so close to harvest, we’ve observed the same benefit of reducing stem-end splitting of sensitive cultivars.

NAA

NAA (Fruitone L; Pomaxa; Refine, etc.) Naphthalene acetic acid (NAA) is a synthetic auxin that delays the breakdown of cells in the abscission zone to control PFD. NAA has been known to reduce preharvest drop for over 80 years. A key benefit of NAA is that it is fast acting when compared to AVG, as a cessation of fruit drop can be observed within 2-3 days after application. NAA can also be incorporated into cover sprays. However, there is no delay of fruit maturation with NAA. In fact, when NAA is applied at high temperatures/rates (> 85◦F/10 ppm) ripening can be hastened due to NAA inducing ethylene production. The PHI of NAA is 2 days.

PFD can be controlled for 7-10 days with a single application of NAA at 10-20 ppm, with 10 ppm being an effective rate. Higher application rates (>10 ppm NAA) may cause fruit softening at temperatures above 85°F.

A split application of 10 ppm NAA provides PFD control for 10-14 days from the first application. Timing of application should be done with anticipated harvest date in mind and an assessment of fruit susceptibility to PFD.

If using summer applications of NAA to enhance return bloom, then a preload NAA application strategy can be considered. Apply NAA at weekly intervals beginning four weeks before date of normal anticipated harvest at the rate of 5 ppm/week. Application can be included with preharvest cover sprays.

If 3-5 fruit drop from a limb or leader (3-4” in diameter) following a firm strike of the limb with the palm of your hand then NAA should be applied or the fruit harvested within 2 days (Penn State Fruit Production Guide 2020).

Retain + NAA

Based on previous work done at NC State by Steve McArtney, the tank-mix combination of ReTain plus a 100% organosilicone surfactant plus 10 to 20 ppm NAA applied two weeks prior to normal harvest provides superior control of fruit drop and firmness retention compared to ReTain or NAA alone.

Harvista™

1-MCP is an ethylene action inhibitor and is widely utilized as a postharvest treatment for numerous horticultural commodities, including apples. A sprayable formulation of 1-MCP was developed and registered in 2014 (Harvista™, AgroFresh Inc., Philadelphia, PA). However, modified application equipment (a proprietary in-line injection system) is required for Harvista™, since premature mixing with water can result in poor efficacy. There has been limited evaluation of Harvista in North Carolina, though other eastern apple producers have adopted this technology. For more information on this product, contact the manufacturer.

What can go wrong?

Efficacy of these PGRs can be influenced by several factors, including tree stress (nutritional, drought, severe insect/mite infestation, etc.), environmental conditions, application timings, and rates. Applying these products to stressed trees is not suggested and inconsistent responses may be observed. Poor efficacy can be observed with late applications to high ethylene producing varieties.

Warm temperatures during fruit maturation is typically observed in the southeastern US. Applying these products during the heat of the day is generally not advisable. Where an organosilicone surfactant is used, this can result in damage to fruit. Warm temperatures near application and harvest can result in more rapid metabolism of the product. In these situations, closer monitoring of fruit maturity is needed to determine if another application is necessary.

Take Homes

When used appropriately, AVG and NAA are both effective PFD control measures. AVG has the added benefit of delaying maturity while NAA is a cheaper option that can be used as a rescue treatment when PFD risk is high since its action is faster than AVG. Used in combination, AVG and NAA provide excellent PFD control. The two can be tank mixed or AVG applied before. Table 1 summarizes these two PGRs and their use patterns to time harvest and control PFD.

Stop-Drop Spray Recommendations

| Goal | Chemical | Rate and Time of Application |

| To delay preharvest fruit drop; delay fruit maturity; and allow time for added fruit-size increase and natural coloration of red varieties. | ReTain | Ingredient (one pouch) per acre plus a 100% organosilicone surfactant at 0.05 to 0.1% (v/v) three to four weeks before anticipated normal start of harvesting using 100 gal/acre or 50% of TRV. To enhance the duration of preharvest drop control/delayed maturity, up to two pouches per acre can be used. Some varieties, such as Gala and Honeycrisp are more sensitive to ReTain and only require application at half rates for efficacy. |

| Preload NAA | NAA | Apply NAA at weekly intervals beginning four weeks before date of normal anticipated harvest at the rate of 5 ppm/week. Application can be included with preharvest cover sprays. This program has also been shown to increase return bloom in the following year. |

| To reduce preharvest fruit drop at or after the onset of fruit loosening or drop. | NAA | Apply at 10 to 20 ppm at first sign of preharvest fruit drop on most cultivars. Use full coverage, 80 to 100% TRV. Higher application rates (>10 ppm NAA) may cause fruit softening at temperatures above 85°F. |

| To delay fruit drop and maintain firmness in late harvested fruit. Provides the most consistent control of fruit drop and softening. | ReTain plus NAA | Apply one pouch of ReTain per acre plus 10 to 20 ppm NAA as a tank-mix combination two weeks before normal harvest. Include nonionic surfactant normally combined with ReTain in the tank mix. Higher application rates (>10 ppm NAA) may cause fruit softening at temperatures above 85°F. |